My Student Experience: Technology, Engineering, and Design Education Students Hone Teaching, Technical Skills at TEECA East

Whether they were constructing a cardboard pachinko machine to sort parts or teaching a history lesson about North Carolina lighthouses, the NC State students who attended this year’s TEECA Eastern Regional Conference took advantage of the opportunities to showcase the creativity they will one day employ as technologists and educators.

“One of the coolest things is making learning fun,” said Laina Hosey, a senior technology engineering, and design major in NC State’s College of Education. “We have so many standards and things to learn and put together … but we had a lot of fun doing it.”

Laina was one of almost 20 students in NC State’s Technology and Engineering Education Collegiate Association (TEECA) chapter who traveled to Rehoboth Beach, Delaware, for TEECA East this year.

At the conference, students have an opportunity to grow as leaders in technology education while collaborating with students from other universities.

“I got a lot of really good experience just talking to other educators and seeing other educators in action,” said Lauren Shackelford, a fifth year industrial and systems engineering major and vice-president of NC State’s TEECA chapter.

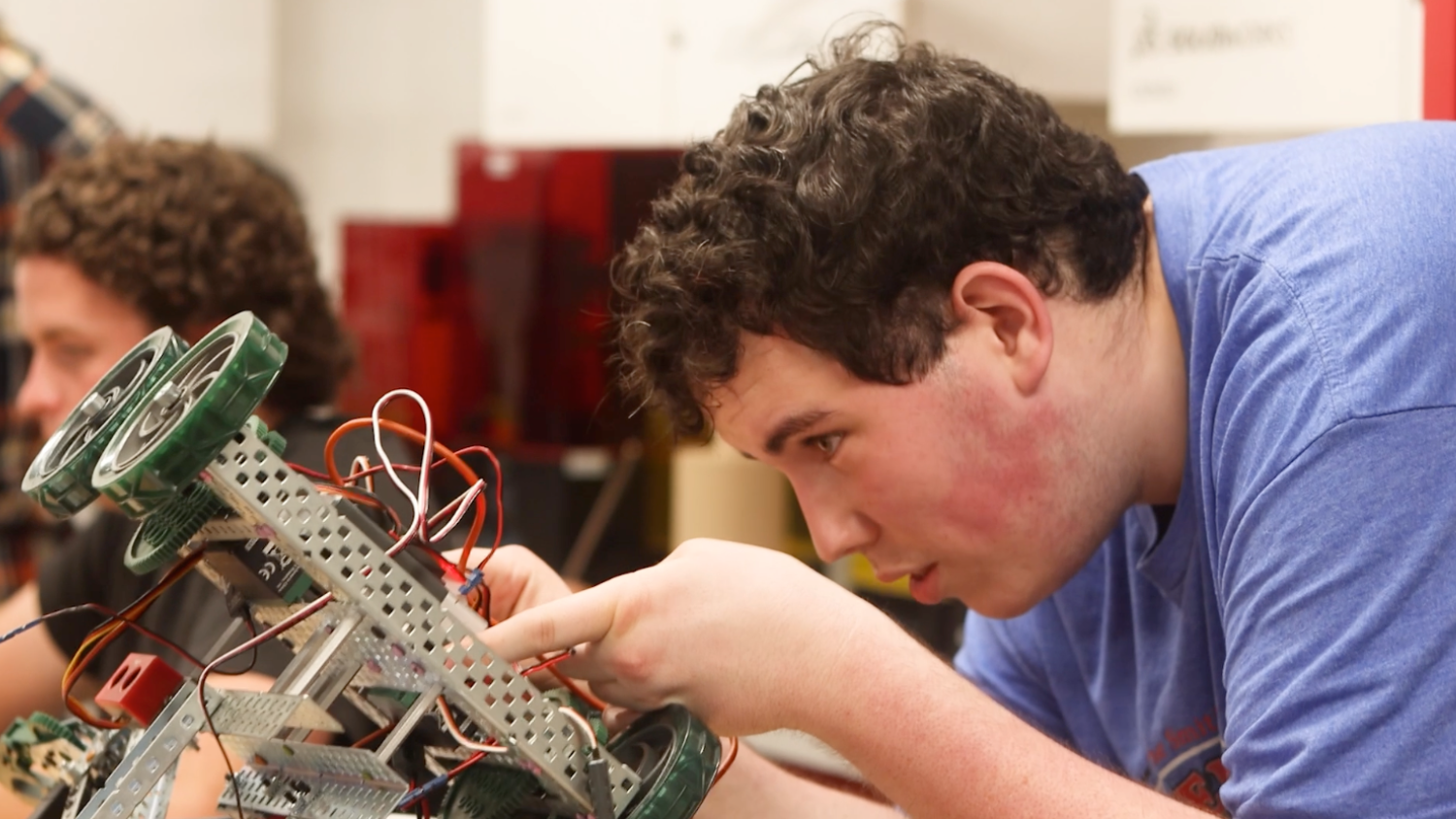

At TEECA East, students competed in challenges representative of the broad range of skills, such as lesson planning, robotics, manufacturing and videography, employed by technology educators.

This is the second year since the COVID-19 pandemic that NC State students have been able to attend TEECA East in person, and this year they won eight awards, three more than last year.

Read more about some of the competitions they took part in below.

Teaching and Technology

A number of TEECA East competitions push students to grow their technical skills while preparing them to teach future students.

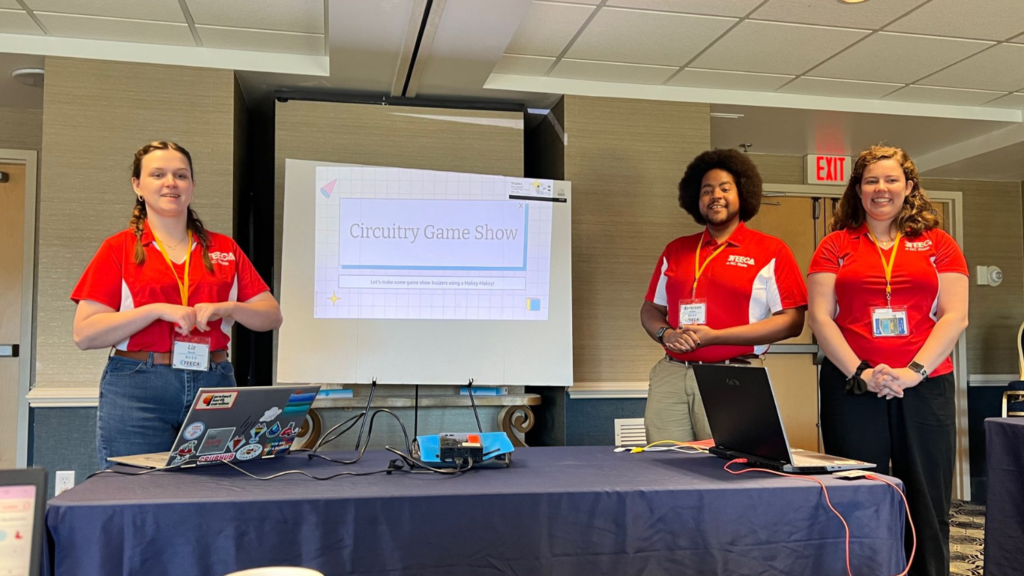

Liz Marsh, for example, had never used microprocessors before, but at TEECA East, she and her team learned enough about the miniature computers, used by brands such as Makey Makey and Raspberry Pi, to take second place in the Teaching Lesson competition.

“You learn really fast,” said Marsh, a senior technology, education, and design engineering major.

In the K-5 STEM competition, participants were required to design and build a lighthouse and then teach a lesson connected to it. Adeleigh Graham — a senior technology, engineering and design education major and president of NC State’s TEECA chapter — and her team decided it would be a perfect opportunity to explore the history of lighthouses in North Carolina.

“When I think of co-teaching, I often think of it being between teachers in the same discipline, but that doesn’t have to be the case,” Graham said. “In our K-5 STEM challenge, we were able to relate something that’s very science and technology focused to a fourth-grade social studies class.”

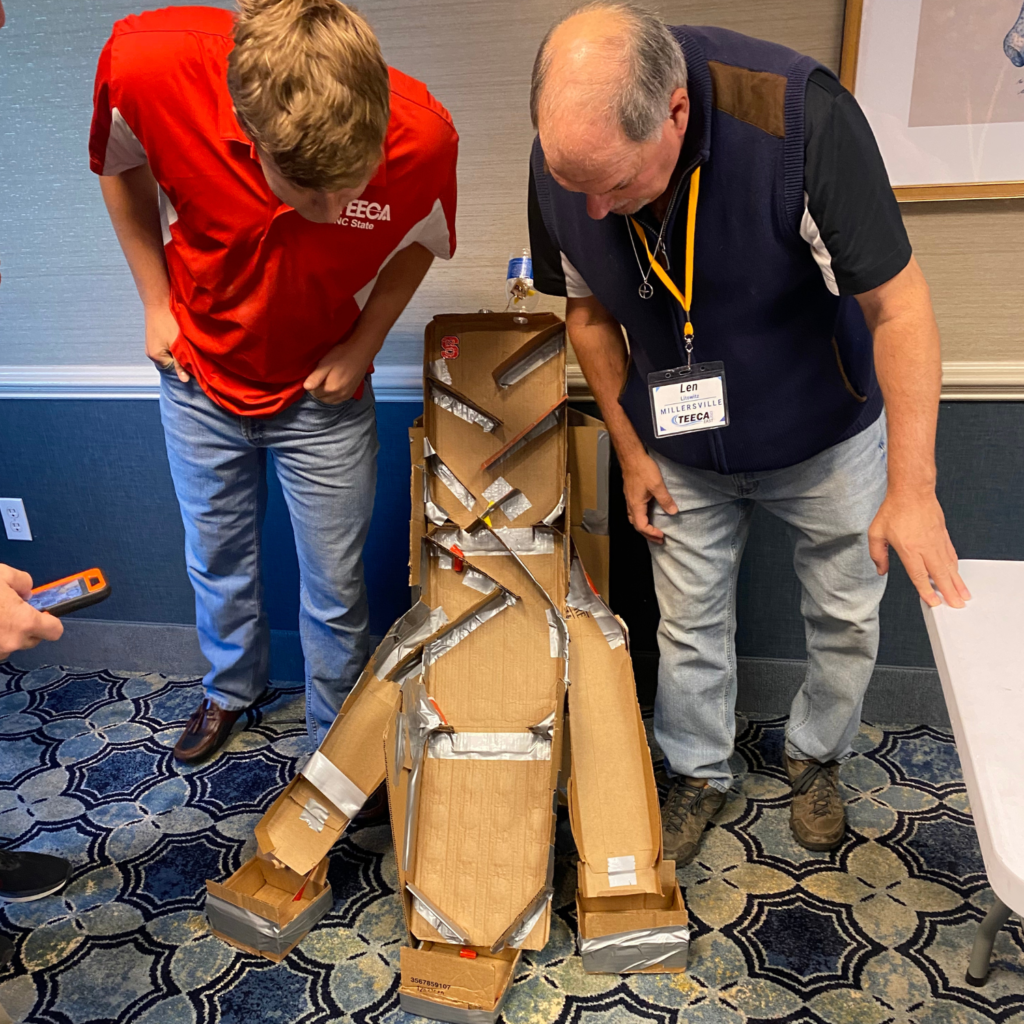

Thinking Inside the Box

The Transportation Challenge required teams to sort and distribute three different parts for shipping. While some teams used 3D printed materials and LEGO EV3 bricks, NC State’s team decided to go low-tech.

They glued together pieces of cardboard from soda and pizza boxes until they had constructed a device that resembled a pachinko machine, which then sorted the objects based on weight as they plunked down to the bottom.

As Liz Marsh said, “Our people did it with trash.”

A Chocolate Factory Conveyor Belt

While the new Willy Wonka musical delves into the origins of the fictional chocolatier, it has little to say about the nuts and bolts of how his factory actually runs. That’s where the Problem Solving competition came in.

Gerard Gaskin, a senior technology, engineering and design education major, and his team were tasked with creating a conveyor belt, similar to those used in the movies, that could transport pieces of chocolate to their eventual destination. Working on the challenge, Gaskin said, helped him gain a better understanding of project management.

“It was problem solving, so I did take some knowledge home from that,” Gaskin said. “That and time management were big things I pulled from this competition.”

Putting it All on the Production Line

“Essentially, it’s like Santa’s workshop.” That’s how Sean Ryan, a senior technology, engineering and design education major, described the Manufacturing Competition, which required participants to design and produce 13 dice vaults, boxes that each held six individual dice.

Their team spent months assembling their manufacturing process and determining what aspects of the project could be done ahead of time in order to make their on-site production line as efficient as possible.

For the cutting mechanism itself, they tested a variety of methods before settling on a cutting mechanism that resembled a large cookie cutter.

“The [judges] were impressed with how we did it because we did it differently than every other college,” Laina Hosey said. “For them to acknowledge what we did well and give us what we can improve on, I feel like it’s invigorating to go back next year.”

- Categories: